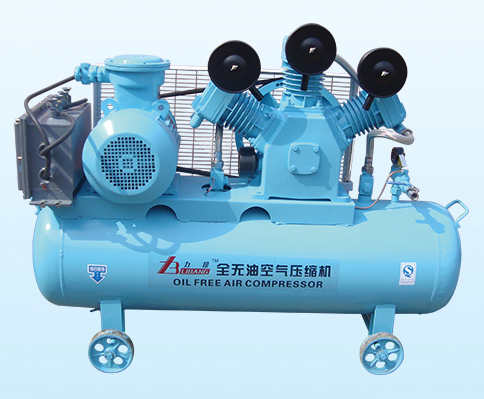

Air compressor is one of the main mechanical power equipment in many enterprises. It is necessary to keep the safe operation of air compressor. Strict implementation of the air compressor operating procedures, not only help to extend the service life of the air compressor, but also to ensure the safety of air compressor operators, the following oil free air compressor manufacturers explain the air compressor operating procedures.

First, in the air compressor operation, should pay attention to the following issues:

1. Keep the lubricating oil in the oil tank within the range of the scale. Before the air compressor operation, check that the oil in the oiler should not be lower than the scale value.

2. Check whether the moving parts are flexible, whether the connecting parts are tight, whether the lubrication system is normal, and whether the motor and electrical control equipment is safe and reliable.

3. Before the air compressor operation, check whether the protective devices and safety accessories are intact and complete.

4. Check whether the exhaust pipe is unblocked.

5. Connect the water source and open the inlet valves to make the cooling water unblocked.

Two, air compressor operation should pay attention to a long period of time after the first start, must be checked, pay attention to whether the impact, stuck or abnormal noise phenomenon.

Iii. The machine must be started under no-load condition, and the air compressor shall be gradually put into load operation after the no-load operation is normal.

Four, air compressor operation, normal operation, should always pay attention to various meter readings, and adjust at any time.

V. during the operation of the air compressor, the following conditions shall be checked:

1. Whether the temperature of the motor is normal and whether the reading of each meter is within the specified range.

2. Whether the running sound of each part is normal.

3. Suction valve cover whether heating, valve sound is normal.

4. Air compressor safety protection equipment is reliable.

6. After the air compressor is operated for 2 hours, the oil and water in the oil and water separator, intermediate cooler and rear cooler shall be discharged once, and the oil and water in the air bucket shall be discharged once per shift.

Seven, air compressor operation found the following circumstances, should immediately stop, find out the reason, and be eliminated.

1. The lubricating oil or cooling water ends up broken.

2. The water temperature rises or falls suddenly.

3. Relief valve failure due to sudden increase of exhaust pressure.

The operating power part of the air compressor shall comply with the relevant provisions of the internal combustion engine.