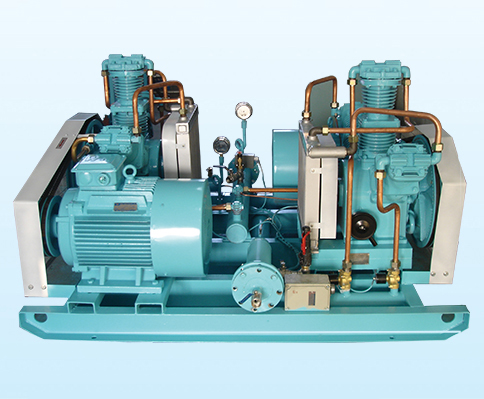

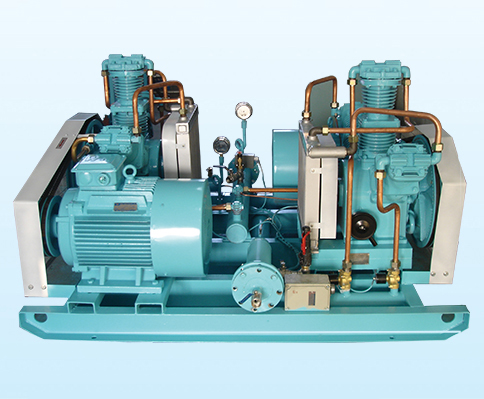

Medium pressure oil-free gas compressor

Explosion-proof medium pressure oil-free gas compressor

Special compressor

Explosion-proof special supercharger

Medical oxygen press

Natural gas supercharger

A compressor is a device for compressing gases. Air compressors are similar in structure to water pumps. Most air compressors are reciprocating piston type, rotating vane or rotating screw. Centrifugal compressors are very large applications.

There are many types of compressors (air compressors) :

1, according to the working principle can be divided into three categories: volumetric, dynamic (speed or turbine), thermal compressor.

2, according to the lubrication mode can be divided into no oil air compressor and oil lubrication air compressor.

3, according to the performance can be divided into: low noise, variable frequency, explosion-proof air compressor.

4, can be divided into: according to the use of refrigerator compressor, air conditioning compressor, refrigeration compressor, oil field with compressor, gas stations, rock drill, pneumatic tools, vehicle braking, Windows and doors opening and closing, textile machinery, the tyre, plastic machinery with compressor, mine compressor, Marine air compressor, medical compressor, sandblasting spray paint.

5. According to the type, it can be divided into fixed type, mobile type and closed type [1].

Positive displacement compressors - compressors that increase pressure by directly changing the volume of the gas.

Piston compressor - is a positive displacement compressor, the compression element is a piston, reciprocating motion in the cylinder.

Rotary compressor - is a positive displacement compressor, compression is achieved by the forced movement of rotating elements.

Sliding vane compressor - rotary variable capacity compressor, the axial sliding vane with cylindrical cylinder eccentric rotor for radial sliding. The air trapped between the slides is compressed and discharged.

Liquid-piston compressor -- a rotary displacement compressor in which water or other liquid ACTS as a piston to compress gas and then expel it.

Roots double rotor compressor - a rotary displacement compressor in which two roots rotors engage with each other to trap gas and transfer it from the inlet to the exhaust. No internal compression.

Screw compressor - rotary displacement compressor, in which two rotors with helical gear meshing with each other, so that the two rotors meshing volume from large to small, so that the gas compression side out. Screw compression components in screw air compressors are manufactured internally using the latest CNC grinder and with online laser technology to ensure extremely accurate manufacturing tolerances. Its reliability and performance can ensure that the running cost of the compressor has been very low during the service life. Adjustable compressors, integrated compressors and desiccant series are new products in L/LS series compressors.