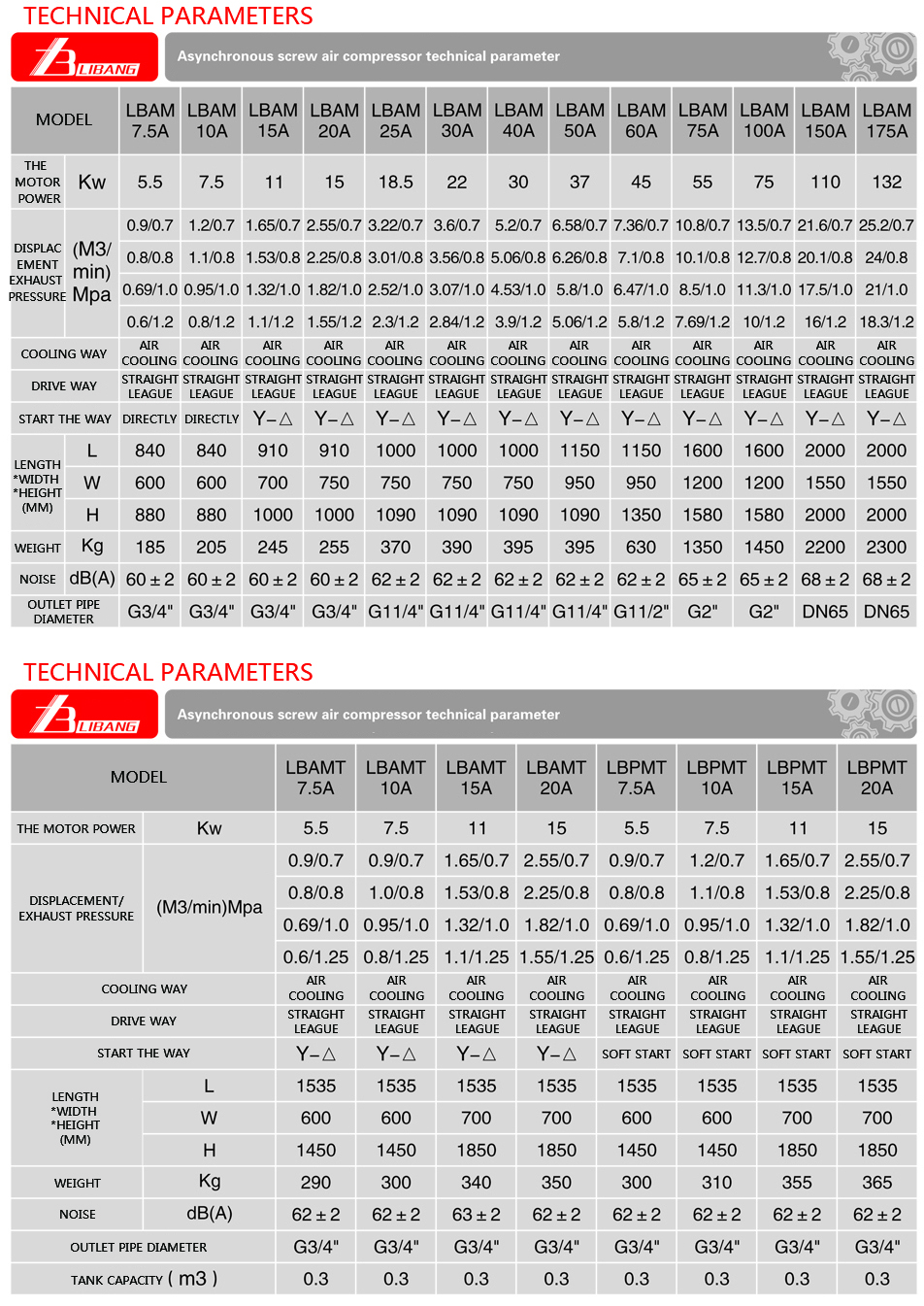

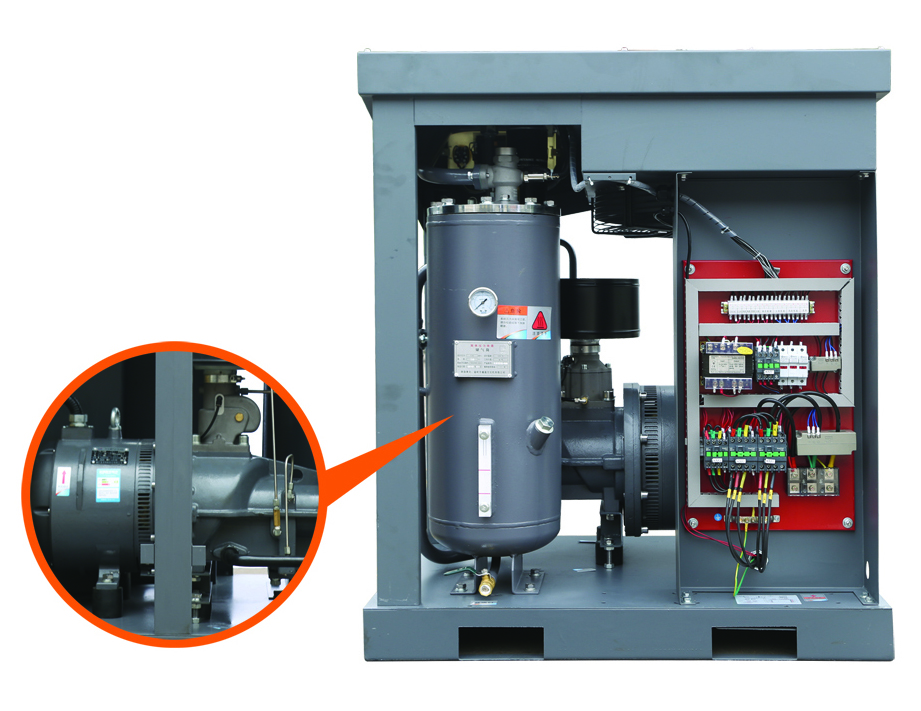

High efficiency, energy saving and convenient maintenance

Asynchronous all-in-one screw air compressor, the connection mode between the main machine and the motor is direct connection, without the need of center bracket, belt, pulley, the transmission ratio is 100%, with the asynchronous motor with the same specifications compared with the efficiency improved by 2-8%. Motor without bearing, oil seal, eliminate motor bearing fault point, save cost, reduce daily maintenance and maintenance.

Simple structure, small size and light weight

The asynchronous integral screw host component is 1/2 smaller than the ordinary three-phase motor component, and the weight is 1/3 lighter than the ordinary motor component. The whole machine has simple structure, small size and reasonable design. The overall size of the whole machine is obviously reduced and the site utilization rate is increased.

Soft start design

Frequency conversion startup mode greatly reduces the impact of compressor startup on the power grid and the mechanical part, and will not cause damage to the electrical equipment.

Synchronization design

There is an invariable relation between the rotor speed and the grid frequency, and no slip. If the frequency of the power network is constant, the speed of the synchronous motor is constant in the steady-state state, which is independent of the load.

Synchronization design

Permanent magnet synchronous all-in-one screw air compressor, the frequency conversion system works under the rated speed in most working conditions, the main machine mechanical noise and wear drop, extend the maintenance and service life.