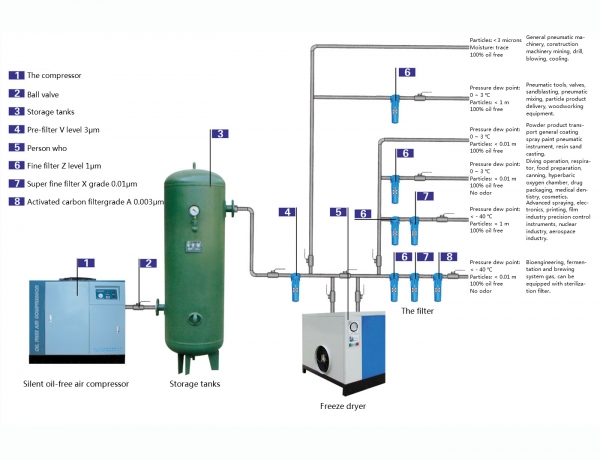

High efficiency and precision filter

C- main pass filter

Can remove a large number of liquid and 3 m above solid particles, to the minimum residual oil content of only 5ppm, a small amount of water, dust and oil mist, for air compressor, after the rear cooler, before other filters, for general protection; It is used as a pretreatment device before cooling and drying machine.

T- air line filter

It can filter liquid and solid particles as small as 1 m, reach the lowest residual oil content of only 0.5 PPM, with trace water, dust and oil mist, used for pre-treatment before a-level filter; Further improve the air quality after the coolers and dryers.

A- ultra high efficiency oil removal filter

Can filter small to 0.01 m of liquid and solid particles, the lowest residual oil content is only 0.0001 PPM, almost all water, dust and oil fog are removed, used for the protection of h-level filter and dryer before, after the cold dryer, to ensure that the air does not contain oil.

H- activated carbon mist filter

It is capable of filtering oil mist and hydrocarbons as small as 0.01 m, with a minimum residual oil content of only 0.003 PPM. It is free of moisture, dust and oil, odorless and tasteless, and ACTS as a final filter for some units that must use high-quality air, such as food industry, breathing, sterile packaging, etc.

High efficiency precision filter technical specification table

Model | Nominal flow rate (Nm³/min) | Size | In and out of the interface |

A | B | C |

LBG-1.0 | 1 | 115 | 290 | 550 | 1″ In the teeth |

LBG-2.0 | 2 | 130 | 575 | 835 | 1″ In the teeth |

LBG-3.0 | 3 | 130 | 575 | 835 | 1¹/2″ In the teeth |

LBG-6.0 | 6 | 130 | 735 | 995 | 2″ In the teeth |

LBG-10 | 10 | 159 | 360 | 1140 | 2″ In the teeth |

LBG-15 | 15 | 159 | 360 | 1140 | 2¹/2″ In the teeth |

LBG-20 | 20 | 159 | 360 | 1140 | DN65 |

High efficiency and precision filter material performance

The filter element level | The main filter material | Pressure of work (MPa) | Working temperature (℃) | Filtration precision (µm) | Liquid water divisor(%) | Residual oil | The smell | The pressure drop of the failure (MPa) | Life hours (h) |

V - level prefilter | Stainless steel mesh, glass fiber | 0.2—1.4 | ≤65 | 3 | 99 | 60% | have | 0.07 | 8000 |

Z level fine filter | Multilayer glass fibre | 1 | 100 | 30% | have |

X-level superfine filter | Multilayer fiberglass and sponge | 0.01 | 100 | 0.01ppm | have | 2500 |

A level activated carbon filter | Activated carbon, glass fiber sponge | 0.01 | 100 | 0.01ppm | not |