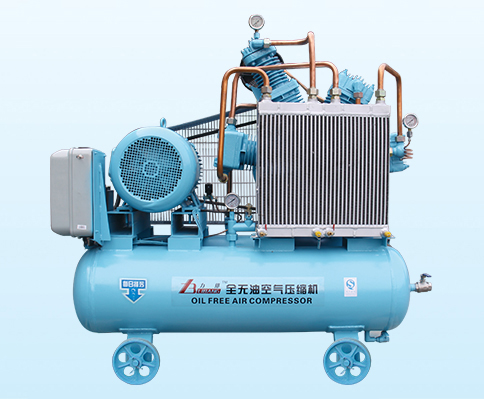

Oil - free air compressor manufacturers of oil - free air compressor chassis maintenance

* view cycle: generally every three months.

* view process:

1. Put the oil-free air compressor in the suspension state, and check it only after it is completely cooled and decompressed.

2. Open the plexiglass window of the case to check whether the balanced iron pin is strong.

3. Check the screws to see if they are loose.

4. The surface finish of internal parts, whether there is wear and lack of meat.

5. Use a wrench to pry the link parts between the balance iron to see if they are loose or painful.

6. Shine the torch light on the rolling parts to see whether the gaps are even and whether they are worn and oval.

7. After viewing, install the plexiglass window of the chassis.

8. Check the case and case case to see if there is any crack.

At this point, the entire viewing process is complete. Here are a few things to note:

1, that is to view the process of the first, let the oil free air compressor in the state of cooling, no pressure. Otherwise, simple damage to the viewer forms on the human body.

2, each view should be recorded in the form, and requires the maintenance personnel signature recognition.