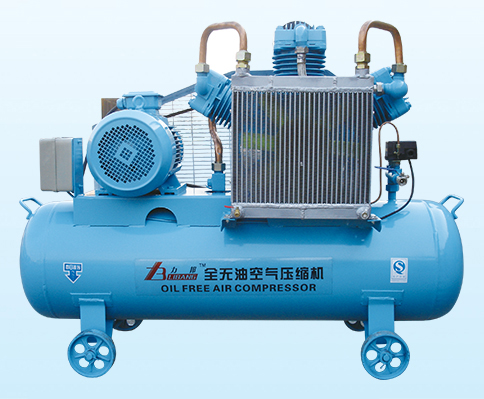

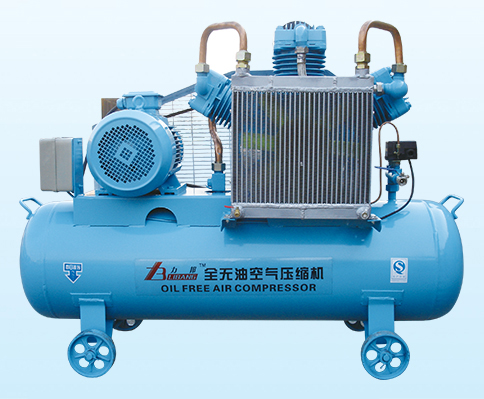

ZW-0.05/8 type oil free air compressor

VW-0.48/8 full oil free air compressor

WW-0.6/8 oil free air compressor

WW-0.8/10 oil free air compressor

WW-1.25/8 oil free air compressor

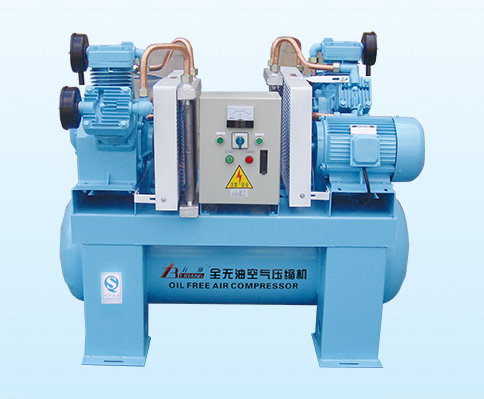

WW-2/8-II type oil free air compressor

WW-3.2/8-II type a all oil free air compressor

Water-cooled oil-free gas compressor WWZ-10/0-10

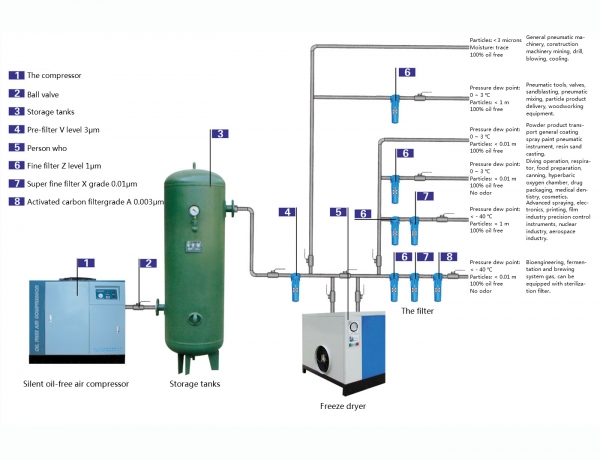

Oil free air compressor features:

The piston ring and guide ring are made of self-lubricating material, and the rotating part is made of sealed bearing with grease added. Therefore, no lubricating oil is required to be added in the work, and the exhaust gas contains no oil and steam, which will not pollute the end product of the user. It is an environment-friendly and energy-saving product. As a general power air source, than the oil air compressor is more convenient to use, low maintenance costs. As the most simple and ideal equipment for providing high quality oil-free compressed air, it saves a lot of equipment expense and maintenance cost by eliminating the complicated oil filtration treatment equipment.

Application: as a general power source, can replace the oil air compressor.

Particularly suitable for hospital air station, pharmaceutical, food and beverage processing, cable inflatable maintenance, petrochemical industry, electronic pneumatic instrumentation, high-grade spraying, powdery and granular gas, air agitation, biological fermentation, environmental protection, film, jet mill, water purification, music fountain, air separation, laser, such as national defense scientific research departments use.

Technical parameters of oil - free air compressor

Number | Model | Volume flow (m³/min) | Exhaust pressure (Mpa) | Power | The pump capacity(L) | The net weight (kg) | Length×width×height (mm) | The interface size(Rc) |

KW | HP |

1 | ZW-0.05/8 | 0.05 | 0.8 | 0.55 | 0.75 | 36 | 73 | 800X350X680 | 3/8 |

2 | VW-0.11/8 | 0.11 | 0.8 | 1.1 | 1.5 | 36 | 78 | 800X400X800 | 3/8 |

3 | VW-0.15/8 | 0.15 | 0.8 | 1.5 | 2 | 36 | 90 | 800X400X800 | 3/8 |

4 | VW-0.22/8 | 0.22 | 0.8 | 2.2 | 3 | 80 | 195 | 1280X440X930 | 1/2 |

5 | VW-0.3/8 | 0.3 | 0.8 | 3.0 | 4 | 80 | 200 | 1280X440X930 | 1/2 |

6 | WW-0.48/8 | 0.48 | 0.8 | 4.0 | 5.5 | 80 | 225 | 1280X440X930 | 1/2 |

7 | WW-0.6/8 | 0.6 | 0.8 | 5.5 | 7.5 | 170 | 262 | 1530X690X1090 | 1/2 |

8 | WW-0.9/8 | 0.9 | 0.8 | 7.5 | 10 | 170 | 302 | 1530X690X1100 | 1/2 |

9 | WW-1.25/8 | 1.25 | 0.8 | 11 | 15 | 270 | 432 | 1350X800X1180 | 1/2 |

10 | WW-1.6/8 | 1.6 | 0.8 | 15 | 20 | 270 | 480 | 1640X780X1460 | 1/2 |

11 | SW-2/8 | 2.0 | 0.8 | 18.5 | 25 | 240 | 580 | 1600X900X1200 | 1 |

12 | SW-2.5/8 | 2.5 | 0.8 | 22 | 30 | 240 | 650 | 1600X900X1200 | 1 |

13 | SW-3.0/8 | 3.0 | 0.8 | 22 | 30 | 240 | 680 | 1600X900X1200 | 1 |

14 | VW-0.12/10 | 0.12 | 1.0 | 1.5 | 2 | 36 | 92 | 800X400X800 | 3/8 |

15 | VW-0.2/10 | 0.2 | 1.0 | 2.2 | 3 | 80 | 198 | 1280X400X930 | 3/8 |

16 | WW-0.4/10 | 0.4 | 1.0 | 4.0 | 5.5 | 170 | 235 | 1420X570X1000 | 1/2 |

17 | WW-0.6/10 | 0.6 | 1.0 | 5.5 | 7.5 | 170 | 290 | 1500X600X1080 | 1/2 |

18 | WW-0.83/10 | 0.83 | 1.0 | 7.5 | 10 | 170 | 330 | 1520X680X1080 | 1/2 |

19 | WW-1.25/10 | 1.25 | 1.0 | 11 | 15 | 270 | 432 | 1640X780X1460 | 1/2 |

20 | WW-1.6/10 | 1.6 | 1.0 | 15 | 20 | 270 | 480 | 1640X780X1460 | 1/2 |

21 | SW-2/10 | 2.0 | 1.0 | 18.5 | 25 | 240 | 580 | 1640X900X1200 | 1 |

22 | SW-2.5/10 | 2.5 | 1.0 | 22 | 30 | 240 | 650 | 1600X900X1200 | 1 |

23 | SW-3.0/10 | 3.0 | 1.0 | 22 | 30 | 240 | 680 | 1600X900X1200 | 1 |

24 | VW-0.2/14 | 0.2 | 1.4 | 3.0 | 4 | 80 | 200 | 1280X400X930 | 1/2 |

25 | WW-0.5/12.5 | 0.5 | 1.25 | 5.5 | 7.5 | 170 | 275 | 1520X650X1100 | 1/2 |

26 | WW-0.42/14 | 0.42 | 1.4 | 5.5 | 7.5 | 170 | 275 | 1520X650X1100 | 1/2 |

27 | WW-0.7/14 | 0.7 | 1.4 | 7.5 | 10 | 170 | 270 | 1510X610X1100 | 1/2 |

28 | WW-0.9/14 | 0.9 | 1.4 | 11 | 15 | 170 | 360 | 1510X680X1100 | 1/2 |

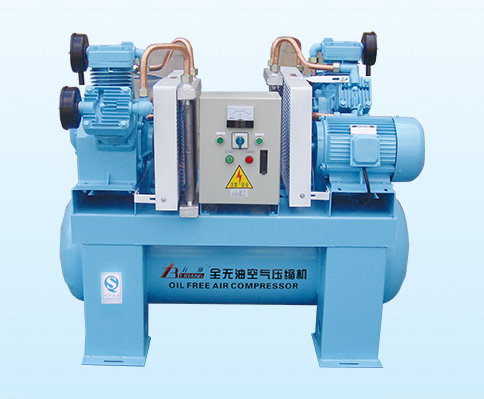

Double main engine features of oil free air compressor:

The two main engines are more flexible and can be used in the application. When starting up, the sequential delay start reduces the reactive power loss of the transformer, reduces the impact on the electrical equipment, and improves the safety factor of electricity consumption. Users can flexibly adjust the load of the two main engines according to the actual gas consumption, which can be used for single or double operation to save the cost of electricity. And the dual host design greatly reduces the possibility of the entire line of production, reduce the loss of users.

Technical parameters of oil - free air compressor (double sets)

| Number | Model | Volume flow (m³/min) |

Exhaust pressure (Mpa) | Power |

The pump capacity(L) |

The net weight (kg) |

Length×width×height (mm) |

The interface size(Rc) |

KW | HP |

1 | WW-2/8-Ⅱ | 2.0 | 0.8 | 7.5X2 | 10X2 | 300 | 680 | 1500X1200X1400 | 1 |

2 | WW-2.5/8-Ⅱ | 2.5 | 0.8 | 11X2 | 15X2 | 300 | 950 | 1500X1400X1450 | 3/2 |

3 | WW-3.2/8-Ⅱ | 3.2 | 0.8 | 15X2 | 20X2 | 300 | 950 | 1570X1400X1460 | 3/2 |

4 | SW-4.0/8-Ⅱ | 4 | 0.8 | 18.5X2 | 25X2 |

| 980 | 1600X1700X1000 | DN50 |

5 | SW-5/8-Ⅱ | 5 | 0.8 | 22X2 | 30X2 |

| 1180 | 1600X1800X1000 | DN50 |

6 | SW-6/8-Ⅱ | 6 | 0.8 | 22X2 | 30X2 |

| 1250 | 1600X2000X1000 | DN50 |

7 | WW-2/10-Ⅱ | 2 | 1.0 | 7.5X2 | 10X2 | 300 | 680 | 1500X1200X1400 | 1 |

8 | WW-2.5/10-Ⅱ | 2.5 | 1.0 | 11X2 | 15X2 | 300 | 762 | 1560X1400X1450 | 3/2 |

9 | WW-3/10-Ⅱ | 3 | 1.0 | 15X2 | 20X2 | 300 | 852 | 1560X1400X1450 | 3/2 |

10 | SW-4/10-Ⅱ | 4 | 1.0 | 18.5X2 | 25X2 |

| 980 | 1600X1700X1000 | DN50 |

11 | SW-5/10-Ⅱ | 5 | 1.0 | 22X2 | 30X2 |

| 1180 | 1600X1800X1000 | DN50 |

12 | SW-6/10-Ⅱ | 6 | 1.0 | 22X2 | 30X2 |

| 1250 | 1600X2000X1000 | DN50 |